Swisstek - III-th Generation

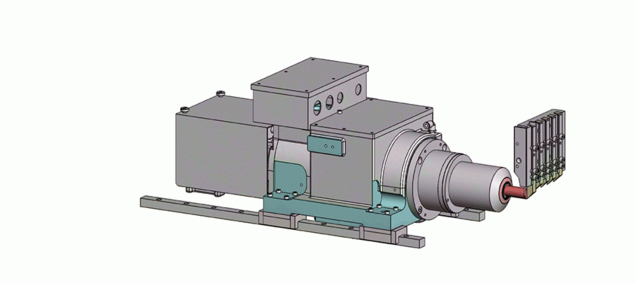

Affordable high tech Swiss type complex turning cells

Our SwissTek Series is an affordable range of Swiss type Turning machines.

SwissTek CNC offers an extensive family of turning machine solutions, specific Swiss-type CNC lathes or Sliding Headstock Type lathes, with or without Removable Guide Bushing (for shorter parts) that can handle diameters ranging from 0,2mm – 26mm (soon 32) at an affordable price without sacrificing quality.

The impressive machining versatility of the SwissTek Series helps to improve productivity, whilst the compact footprint and low energy consumption make these machines easy to accommodate and cost-effective to run.

With a flexible set-up for turning and milling and a removable guide bush for shorter parts (shorter bar remnant = more parts per bar), the Robotturn SwissTek series is ideal for producing parts accurately and efficiently.

All SwisTek Series machines come fully loaded with a high end control, revolving guide bushing, removable guide bushing for short parts, part catcher, part conveyor, chip conveyor and full hydrostatic bar feeder. Each machine we sell is backed by our experienced service department and is guaranteed to deliver the most value for your money.

Robotturn/SwissTek works hard to offer the highest quality products available at an offordable pricing because quality parts and craftsmanship keep your machine running longer and more efficiently.

SwissTek - 3 MODELS - 3 SIZES

High speed swiss type turning Cells - Sliding Head turning lathe - CNC Lathes for Bar Work

A-4 Series

1-Spindle - 4 axis

| X-Y-Z-C Axis | with driven tools |

| ø12 | SwissTek-12A4 |

| ø20 | SwissTek-20A4 |

| ø26 | SwissTek-26A4 |

A-7 Series

2-spindle - 7 axis

| X1-Y-Z1-C1-X2-Z2-C2 | with driven tools and sub spindle |

| ø12 | SwissTek-12A7 |

| ø20 | SwissTek-20A7 |

| ø26 | SwissTek-26A7 |

A-8 Series

2 spindle - 8 axis

| X1-Y1-Y2-Z1-C1-X2-Z2-C2 | with driven tools and subspindle |

| ø12 | SwissTek-12A8M |

| ø20 | SwissTek-20A8M |

| ø26 | SwissTek-26A8M |

Robotturn SwissTek A4 Series

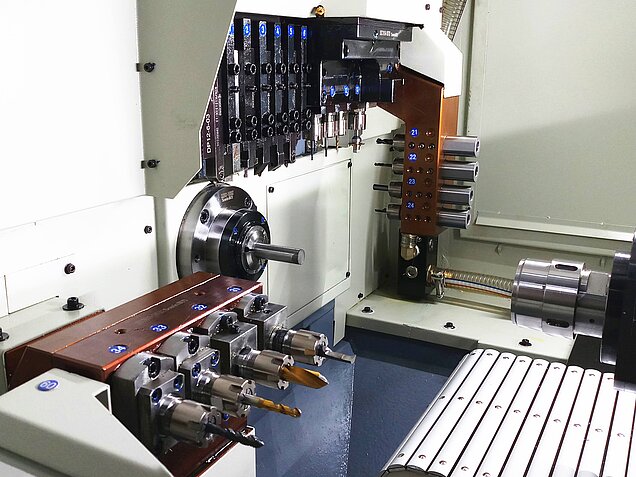

X-Y-Z-C Axis with driven tools

SwissTek-12A4

SwissTek A4 - Single Spindel - Φ12

SwissTek-20A4

SwissTek A4 - Single Spindel - Φ20

SwissTek-26A4

SwissTek A4 - Single Spindel - Φ26

Robotturn SwissTek A7/A7M Series

X1-Y-Z1-C1-X2-Z2-C2 with driven tools and subspindle

SwissTek-12A7

SwissTek A7 - With Sub-Spindle - Φ12

SwissTek-20A7

SwissTek A7 - With Sub-Spindle - Φ20

SwissTek-26A7

SwissTek A7 - With Sub-Spindle - Φ26

Robotturn SwissTek A8 Series

X1-Y1-Y2-Z1-C1-X2-Z2-C2 with driven tools and subspindle

SwissTek-12A8

SwissTek A8 - With Sub-Spindle - Φ12

SwissTek-20A8

SwissTek A - With Sub-Spindle - Φ20

SwissTek-26A8

SwissTek A8 - With Sub-Spindle - Φ26

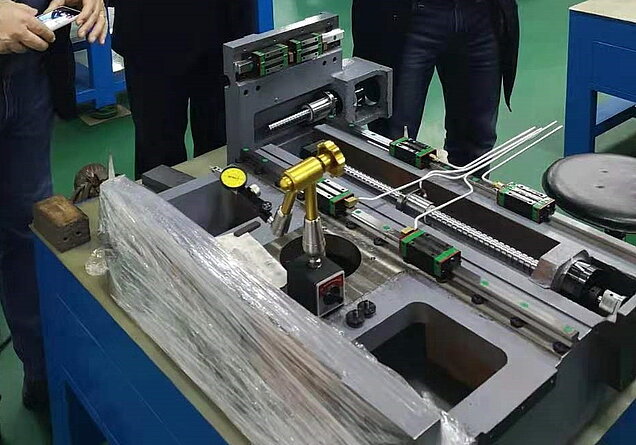

Single piece casted bed

Machine-bed high precision machined in ONE single Clamping

The lathe bed is made of Meehanite casting and built with high rigidity casted in a single whole piece. The box type internal structure is a highly rigid design. The unique rib structure is made with high-quality casting to ensure greater stability and accuracy in heavy-duty applications.

PERFORMANCE ADVANTAGE

Much more stable

Much more accuracy

Much more anti-shocking

High precision lineair guideways and Ball-screws

High precision powerful direct drive spindle motors with forced oil cooling

NO Belt drive - High speed acceleration and deceleration

10.000 rpm spindle speed standard for all SwissTek Machines

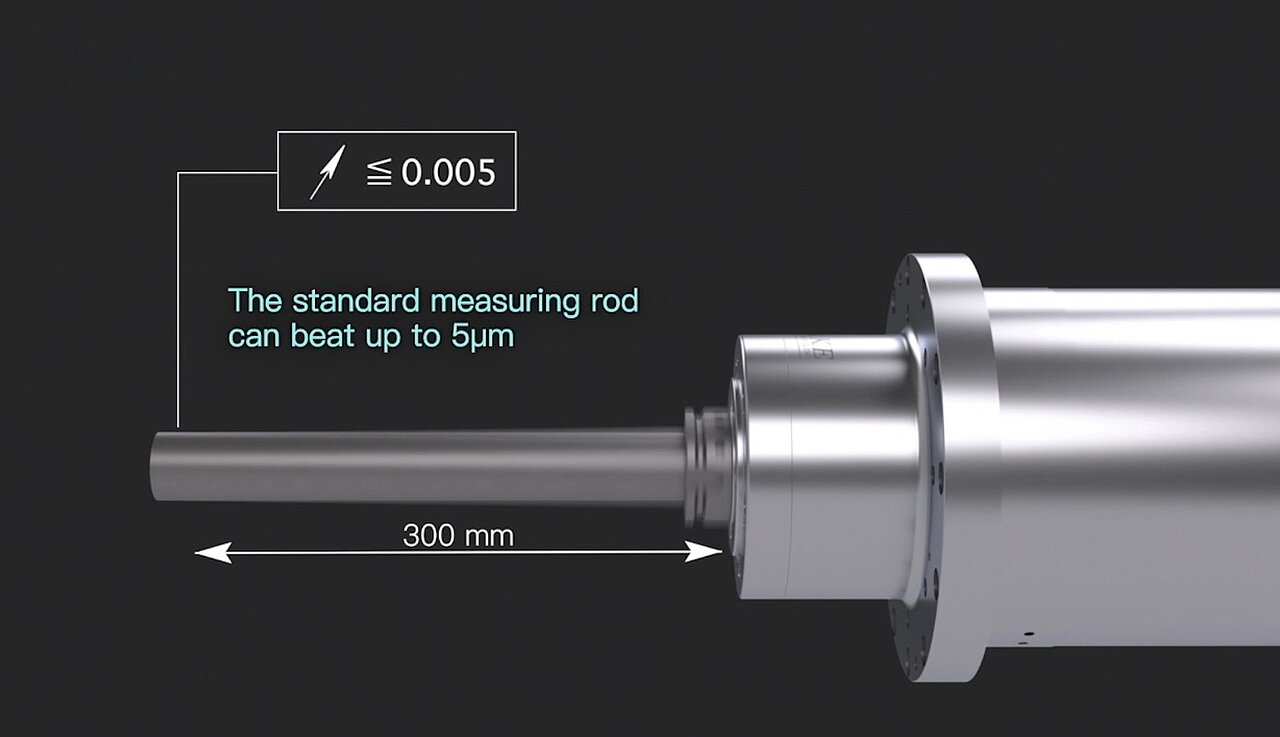

Advanced Spindle Technology

The built-in spindle design reduces centrifugal force effect and restrains spindle vibration,

which increases the spindle life span and improves long-term machining accuracy.

Built-in motor spindle on front and back spindles

Built-in motors are extremely compact and achieve maximum rigidity, a requirement for achieving maximum speeds and exact concentricity.

Built-in motor spindle have high power up to high speed and maintain high precision and low vibration all in one simple mechanical structure.

Built-in main and back spindle motors increase tooling accuracy.

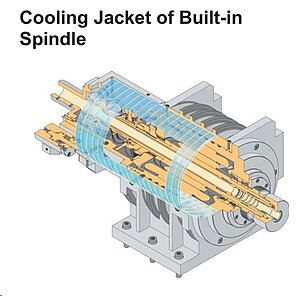

Precision High Responsive Temperature Control with oil cooler: each motorized spindle is equipped with an internal and external temperature sensor.

Circulating oil cooling: The cooling circulating channel is used to cool the spindle in order to keep its temperature within a certain range and ensure the service life and axial accuracy of the spindle.

High dynamic rotation accuracy =

High gloss effect result + good surface machining quality = good surface texture.

High static rotation accuracy =

The end face run-out of the shaft end of the motorized spindle and the run-out in the taper hole are ≤0.003mm

The vibration of the spindle is ≤0.8mm/s.

Water Cooled spindle Motors

Build in spindles with constant temperature control

The spindle really is the heart of the machine and is designed with the application and user specifications in mind. Regardless of what type of machine you are running, the spindle allows the machine to function. Water cooling increases the spindle life drasticaly, keep the high precision tolerances of the machining within strict tolerances and reduce maintenance costs .

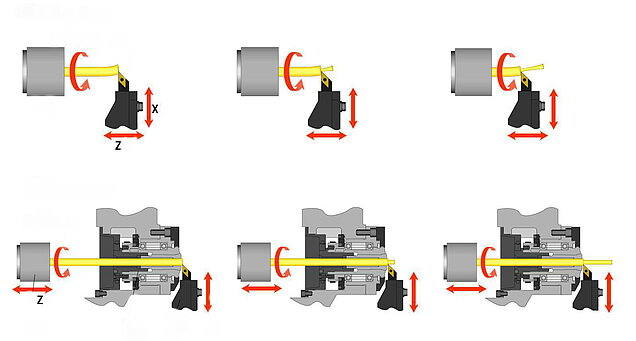

Hybrid Guide Bush

Convertible to Chucker in Minutes

The flexibility of the Swisstek Series is enhanced by its ability to switch between Guide Bush Mode (Swiss type) and Non Guide Bush Mode. With the rough material chucking option, a user can easily convert the SwissTek series to run without the guide bushing. For parts with less overhang (machining length less than 3 times the bar diameter ), the rough material chucking option allows the main spindle to extend into the cutting area.

This added capability lowers running costs by leaving a shorter bar remnant and allowing the use of less expensive non-ground bar

Changing from one configuration to another only takes minutes, allowing the user to choose to run the machine either with or without guide bushing as the needs change. A special interfacing mechanical design of guide bush can be mounted or dismounted based on the actual situation. It is more flexible in use and save cost on facility and space in the factory.

With Guide Bush | Without Guide Bush |

| Suitable for long bar work-piece: increased precision | Suitable for short workpieces : reduced losses |

Convert to chucker mode in minutes

With the increase in material cost in recent years, it’s great that SwissTek Series have chucker mode to reduce waste. In chucker mode, the machine doesn’t require the space between the guide bushing and the collet so there is less bar remnant. Chucker mode does not require the use of ground bar stocks, so it is suitable for cheaper cold-drawn bar machining.

In addition, the powerful chucking force enables heavy cutting, minimizes roughness and improves roundness. The user can choose between guide bushing mode or chucker mode according to the length of the part to be produced and be able to convert to chucker mode in minute

Swiss-type CNC screw machines

Like other kinds of lathes, a Swiss-type CNC screw machine allows workers to cut, drill, or otherwise manipulate a workpiece along an axis of rotation in order to guarantee symmetry along that axis. It gets its name from the region it was originally invented in, as Swiss watchmakers initially used them to make the tiny screws for clocks, which helped cement their reputation for making the best timepieces on the entire planet. Today, a Swiss-type CNC, also known as a Swiss Screw Machine, is a type of lathe that is perfect for manufacturing a huge range of parts and pieces.

The Difference

The quality that makes a Swiss CNC screw machine unique from other machines is that it provides material with additional support through what’s called a guide-bushing. The guide-bushing is fitted around the material and prevents a large amount of the bar stock being exposed, which provides rigidity and allows the machine to hold a tight tolerance better than other kinds of lathes.

The Wide Range of Possibilities

While the name Swiss screw machine implies that it is only useful for making screws or other threaded parts, there is actually a wide range of projects and parts that this machine is capable of making. Because of the rigidity and support that the machine provides, turned parts that are long, slender, and detailed are particularly well-suited to being made by a Swiss-type lathe. Of course, Swiss screw machines aren’t only limited to the small and slender. All kinds of parts can be machined on them, to the point where the all major manufacturers in the defense, medical, and aerospace industries rely on Swiss-Type CNC Screw Machines to make many of the parts that their complicated designs include.

A Swiss CNC screw machine is a fantastic addition to any manufacturing floor.

Difference for your parts when using a guide bush or not

Easy removable coolant tank and chip conveyor for cleaning - Independant from Machine

No thermal contact with coolant and Machine bed : Thermal much more stable production.

Why using a Swiss Style Lathe?

A Swiss Lathe is a type of lathe whereby the holding mechanism or collet is recessed behind the guide bushing. The Swiss lathes are also commonly known as Swiss screw machines, Swiss automatic lathes or Swiss turning centers. The Swiss lathe differ from the traditional lathes in the way that the holding mechanism or collet that holds a bar stock will not be exposed directly to the lathe bed and the tooling. This particular configuration provides this specific machine tool a number of benefits over the traditional type lathes.

The advantages of the Swiss lathe over traditional lathes are largely due to the fact that it utilizes guide bushing. The guide bushing purpose is to offer an additional support to stock material when the part is machined or turned. This guide bushing is fitted closely yet not tightly to surround the bar-stock materials.

The support of this bar-stock material means that the functions of the guide bushing act in a similar fashion as steady-rest does on carriages of traditional lathes.

The Swiss-style lathes typically hold a better tolerance on the parts as turning operations will be conducted closely to the guide bushing.

The guide bushing offers rigidity to turned parts due to the fact that a very small amount of the stock will be exposed once they have left the bushing and until such stage that the turning tools have been engaged.

The guide bushing offers significant rigidity to the stock and these machine types are significantly well-adapted to holding a tight tolerance.

Another benefit of the abilities of the Swiss-style lathe is that they have the abilities to turn the small-diameter parts. Alternatively, they can turn parts that have a larger length-to-diameter ratio. Chatter of tools is also minimized due to the guide or tool bushing position.

Flexible systems based on a standard platform to solve a wide range of handling tasks and with multi-industry applications.

Robotturn has the technical knowledge and experience to handle the most demanding and challenging projects from concept to a fully commissioned automated turning systems. With our extensive portfolio of standard equipment to draw upon, Robotturn will manufacture a bespoke system to suit your requirements and needs.

The robotturn SwissTek Swiss type lathes offers low cost, high mechanical reliability, excellent versatility and short cycle times with a wide variety of components. An installed system is easy to operate and has the added benefit of a short set up time between products. The shortest possible payback time and minimal operator intervention are at the forefront of all Robotturn systems. With the Robotturn it is possible to automate small or large batches and achieve good profitability even with annual volumes as low as a few hundred components. The Robotturn philosophy is to deliver a system that is “Future Proof”.